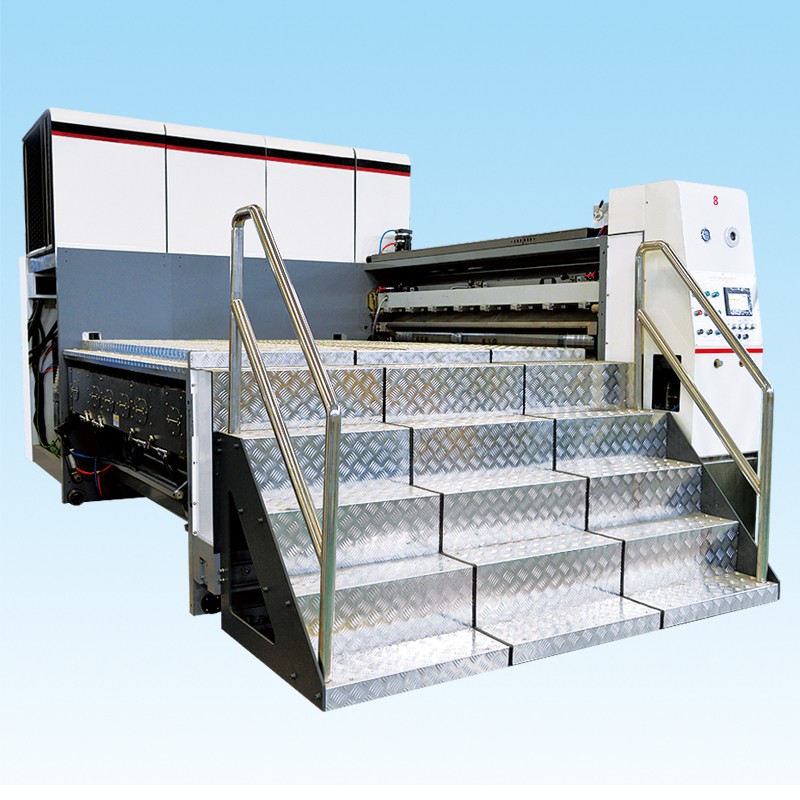

Feeding unit

(New type Avoid pressure servo front paper)

1.Adopt leading edge feeding system to adjust paper feeding length according

to cardboard specifications.

2.Cardboard side pusher function.

3.Back shield up and down, moving is electric, adjusting easy and accuracy.

4.Adopt double row feeding, large tension, make sure the large size carton printing.

5.With skip feeding suction and return to zero device.

6.The host adopt synchronous belt transmission, transmission balance, can absorb

vibration, low noise, economic operation, etc.

7.Option for servo feeder system.

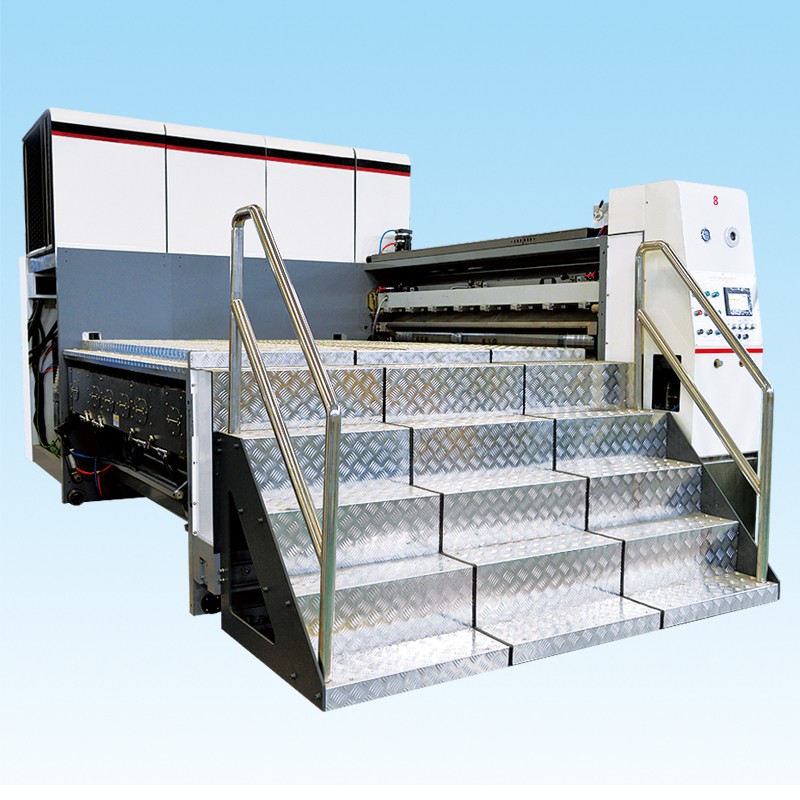

Printing unit

1.The table space with electric adjustment, PLC control digital display.

2.The feed rollers with new ceramic grinding process, minimal wear, friction, long life.

3.Platen roller, using a seal between the baffle to ensure the vacuum pressure

between the units, and the shaft attached to the electromagnetic clutch brake mechanism.

4.Work table adopt high pressure centrifugal fan, by the inverter to control the size

of the wind, the bellows damper size can be automatically controlled to achieve the

role of trace amounts of correction.

5.Printing roll through dynamic and static balance correction, hard chrome plating and grinding.

6.Roller racking stopper double protection, sliding with electric adjustment, and an

automatic return of function.

7.Ink with automatic leveling, automatic leveling shutdown ink to prevent ink drying

affect print quality.

8.The doctor blade system adopts the domestic single blade system (optional with

American Sun Company doctor blade).

9.The two-way pneumatic diaphragm pumps, ink supply amount is controlled by PLC,

automatic cleaning cycle and ink.

Drying unit

1.Independent drying system using infrared mode, fast drying water-based ink

printing surface to avoid the phenomenon out of ink.

2.The dry area is divided into three sections, adjustable range, energy conservation.

3.Electrically adjustable clearance table and drying system.

4.The need to also increase the UV drying function, two for aqueous and UV coatings,

avoid dragging flower phenomenon occurs when die-cutting.

Die-cutting unit

Die-cutting unit

1.The use of a separate double servo drive, make sure that the print sync.

2.The paper guide, lower shaft gap using two-way self-locking device, digital display.

3.Die pads independently controlled servo roll (excellent roller pads) may at any time

amend the line speed to compensate.

4.Die rolls from servo motor control, reducing the transmission link error.

5.The phase adjustment device directly by the servo motor, the exact place.

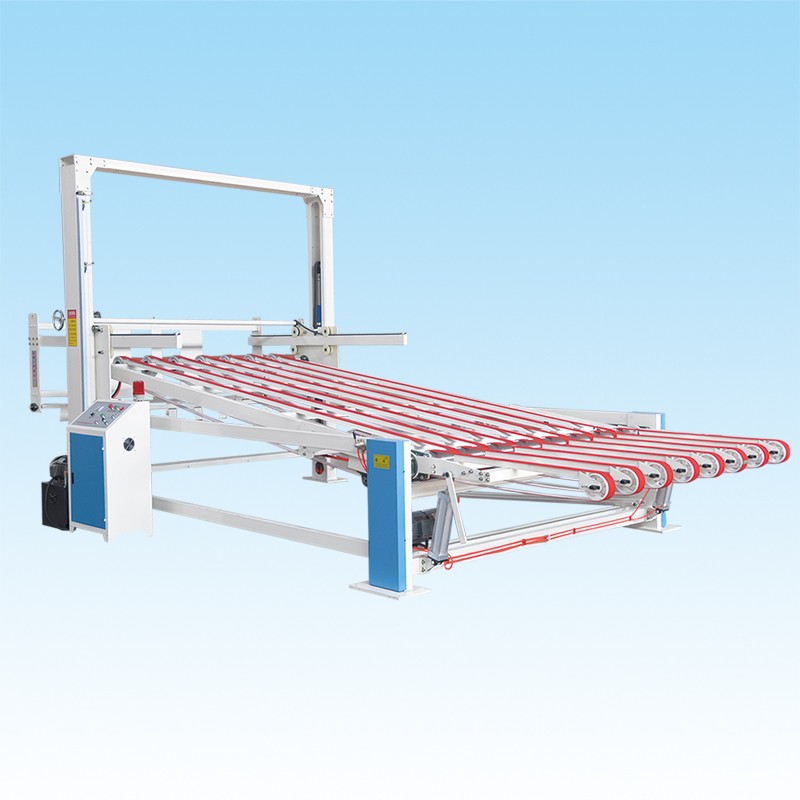

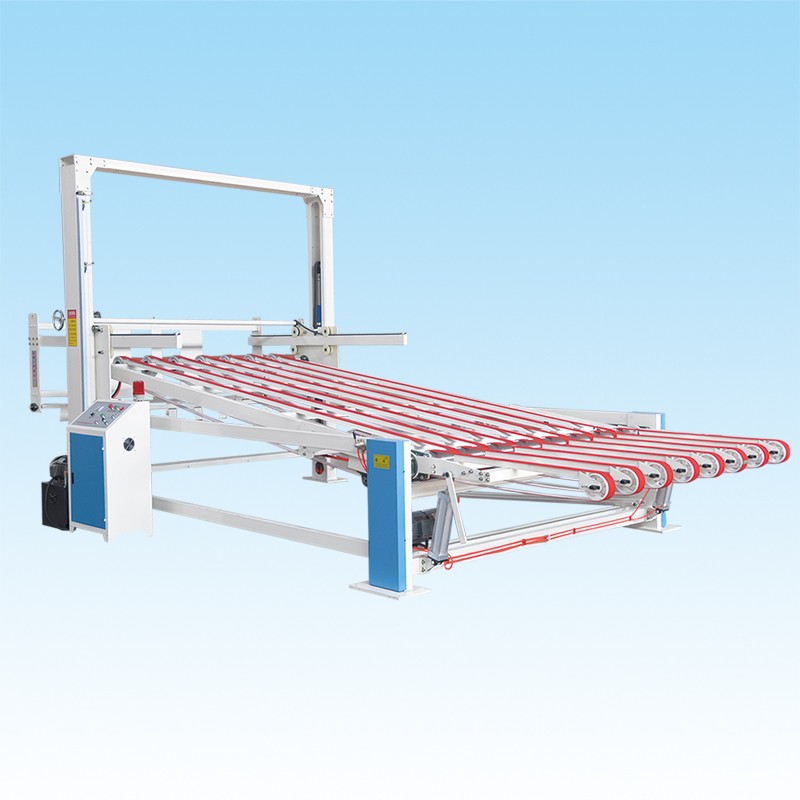

Hydraulic stacker:

1.Bin arm using pneumatic operation, manual control.

2.Bedtable lifting, hydraulic station double hydraulic cylinder drive, to ensure

the safety of operators.

3.Stacking, using a flat wrinkles climbing belt and steel clamping device, so that

the stacking order and tidy.

4.Hold paper feeder can be adjusted to hold the opening width, with a batch

accumulation function.

5.The use of side shoot baffles to ensure more orderly stacked cardboard.

6.Electric enforce the use of PLC programming control, independent of the

operating electric box.

7.Optional vibration stripping and lateral waste function.

8.Stacker height: 1600mm.

Die-cutting unit

Die-cutting unit