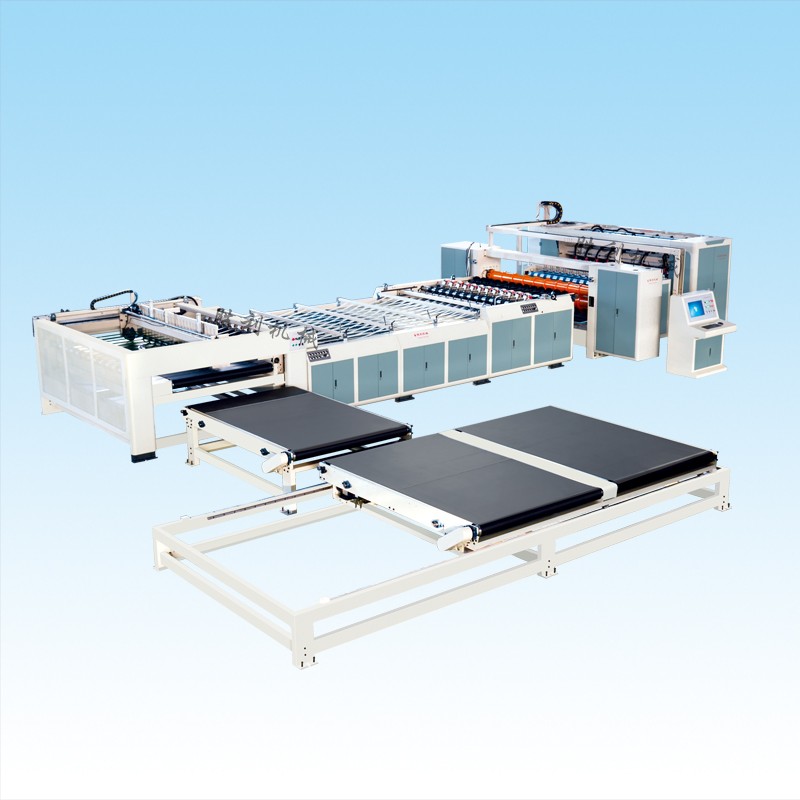

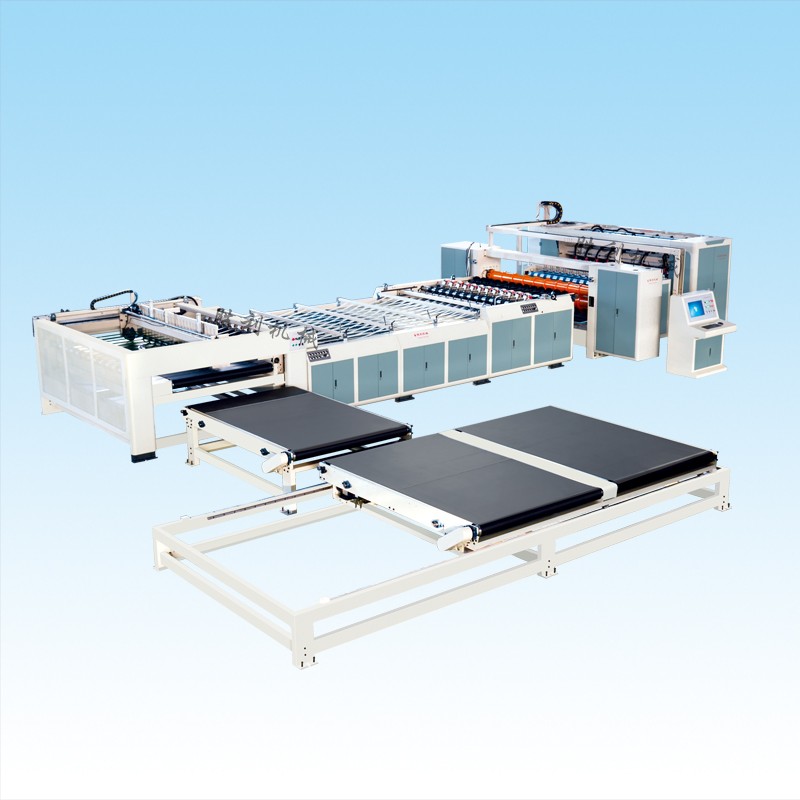

Single layer corrugated paperboard production line is the special equipment to produce the single layer corrugated paperboard. It mainly includes mill roll stand, single facer, preheater, single layer conveyor, single layer slitter socrer, single layer cut off , stacker, steamed heating system, air compressor system and glue making system etc. The flute shape is UV more looks like V shape, the flute includes A、C、B、E four in total. Design speed 150、200、250m/min, the working width is 1800mm、2200mm、2500mm、2800mm.

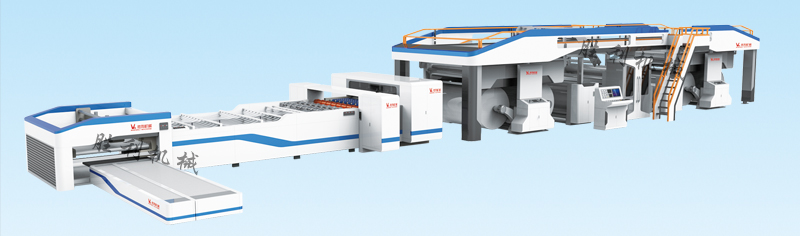

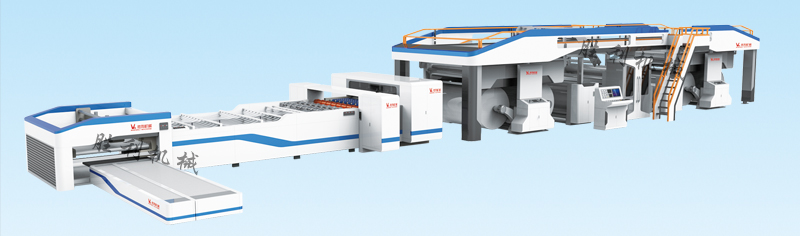

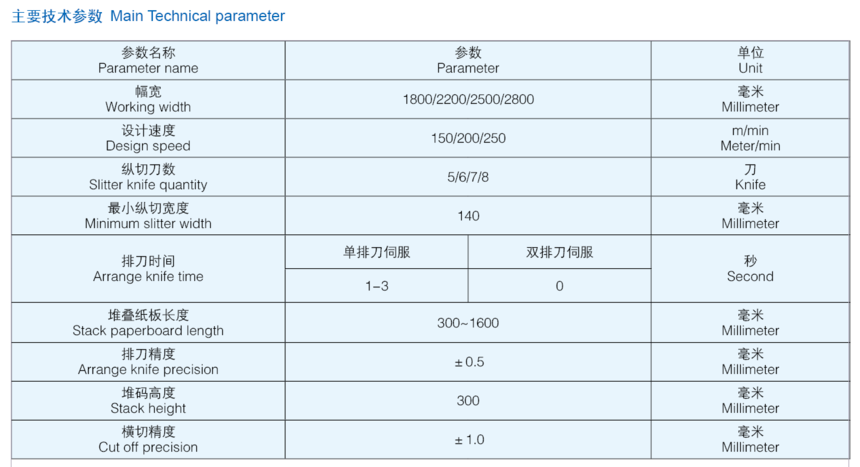

DZQ2 Fully Automatic Single Layer Slitter Machine

* Separate servo control of slitting knife arrangement, fast, accurate and reliable, single row slitter can realize 1-3 seconds to change orders, optional double row slitter can realize 0 seconds to change orders.

* Alloy steel thin knife slitting, automatic grinding, automatic lubrication, long using life, high cutting quality

* Tungsten steel alloy knife paperboard, automatic or manual sharpening, to achieve high quality cutting.

* Precise gear and rack drive, high mechanical positioning accuracy, quick ordering, accurate and reliable.

* Slitting speed adopts servo motor, servo control, automatic synchronous cardboard manual.

* Slitter and cut off machine split design, convenient tool change and maintenance.

* Standard equipped with waste suction mouth, left and right waste suction mouth position permanent magnet synchronous servo control to follow the edge knife synchronous adjustment.

* Standard communication interface, control interface, can be connected with the production management system, automatic order change and order management.

* Single slitter minimum paper slitting size is 140mm, double slitter minimum paper slitting size is 0mm.

*Speed:200、250m/min; Working width:2500mm、2800mm。

DZQ1 Automatic Single Layer Slitting Machine

* All use computer control, realize automatic change order, reduce the waste brought by the shutdown, thus greatly improve the production efficiency.

* Super thin blade separate paper, auto / manual sharp knife, with long using life, it can achieve high quality cut effect.

* Slitter scorer knife change order adopt independent servo control, order change time 3-8s.

* Adopt high precision ball screw , high quality linear guide rail ensures accurate cutting.

* Equipped with waste collect pot to take the waste paper away.

* Slitter output part adopt up and down belt transmit to the cut off machine position.

* It adopts high quality human-machine interface and high performance PLC to realize automatic change and reservation management and storage.

* Minimum siltter width 140mm.

*Speed:150m/min、200m/min; Working width:1800mm、2200mm.

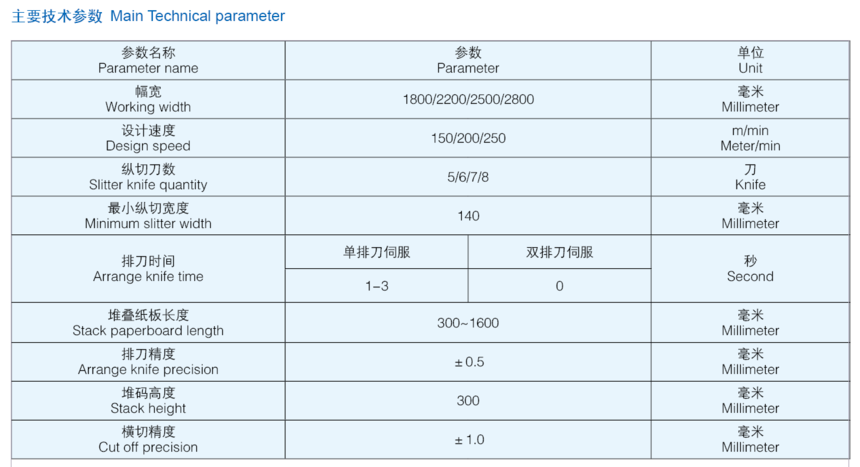

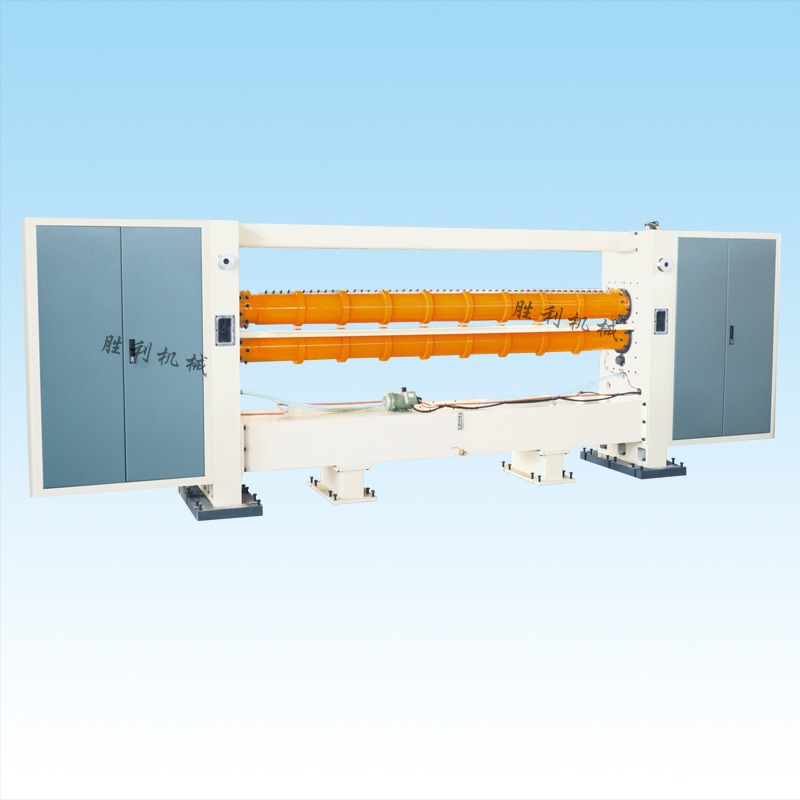

DHQ2 Automatic Double Drive Spiral Knife Cut Off Machine

* Mainframe structure, modular design, precision machining, precision assembly, long-term stable operation of equipment.

* Alloy steel thin-walled spiral cutter shaft, precision needle roller bearing support, low inertia, high stiffness.

* Alloy steel precision helical gear transmission, small backlash, low noise, alloy steel double aide sawtooth spiral knife cross cutting, smooth, neat, accurate paper cutting.

* Adopt high quality AC servo motor, imported special servo driver control, low energy consumption, cutting precision.

* With multi-group order processing function, automatic replacement of the next batch of orders warning, simple and convenient operation.

* Using single-layer spiral knife, smooth cutting, high efficiency.

* The spiral knife is made of special materials, the structure of the knife roller is reasonable, and the service life of the cutter is long.

* The mechanical structure design is reasonable, the mechanical shape is beautiful.

* With automatic lubrication system, gear, bearing cycle lubrication, heat dissipation.

* Cutting accuracy: ±1mm.

* Cutting length range: 300-9999mm.

*Speed:200/250m/min; Working width:2500mm、2800mm.

DHQ1 Fully Automatic Single Layer Spiral Cut Off Machine

* Fully computer controlled, high precision cutting different size of paperboard, automatic change and provide warning signal before change.

* Main frame structure, precision machining, precision assembly.

* Knife roller adopts double helix structure, scissors cutting, high efficiency, smooth transmission.

* The spiral cutter is made of special alloy material, the service life of the cutter is longer.

* Alloy steel precise helical gear transmission, small side clearance, low noise, smooth cutting, accurate, neat.

* German forward servo driver and high quality AC servo motor, achieve high precision, low energy consumption.

* High quality industrial computer control system, standard 16 inch hd display, easy to operate on site.

* Cutting accuracy: with uniform speed ≤ ±1mm.

* Cutting length range: 300-9999mm.

*Speed:150m/min、200m/min; Working width:1800mm、2200mm.

DDM4 Automatic Small Basket Double Station Stacker

* The power adopts servo motor, servo drive control paperboard conveying, conveying speed and cardboard synchronization.

* The three belts are equipped with independent power drive, easy to complete the discharge and stack of cardboard at different speeds and lengths of cutting

* Pneumatic control batch, computer automatic counting, automatic order change fast, accurate, single、double station receiving paperboard.

* Lifting type paperboard receiving platform, computer servo control lifting, stacking is stable and tidy.

* Back baffle servo control positioning, quick order change, accurate adjustment.

* Servo motor and servo driver control paperboard horizontal output, stacking up to the set number of automatic horizontal discharge of paper.

* All belt shafts and guide paper shafts are chrome plated, beautiful and durable.

* Stacking length: 300mm-1600mm.

* Stacker height: 300mm.

* Design Speed: 200m/min、250m/min.

*Working width: 2500mm、2800mm.

DDM1 Automatic Small Basket Stacker Machine

* Automatic basket stacker, automatic computer control, precise counting, quick order switching, automatic batch changing, order changing, smooth lifting and neat stacking.

* The conveying section adopts three-section frequency conversion servo conveying, which is combined with vacuum adsorption to ensure neat stacking of paperboard.

* Three groups of spring battening press paper guide to ensure paperboard neat and stable transportation.

* The batch ejector structure between two and three sections, automatic counting, batch, ensure the accuracy of stacking.

* Tailgate servo control, automatic computer adjustment, automatic change of orders, fast, accurate, stable.

* Flat belt basket stacking platform, computer control up and down, stack steadily and neatly.

* Automatic computer control cardboard horizontal output, stacking reach the set number then automatic horizontal output the paperboard.

* Output paperboard side standard equipped with transmit paperboard rack for easy packing and stacking.

* Stacking length: 300mm-1600mm.

* Stacker height: 300mm.

* Design Speed: 150m/min、200m/min.

* Working width: 1800mm、2200mm.

Machine introduction:

The equipment is the whole process of automatic control of the glue making process, according to the process, raw materials and weather changes can automatically modify the formula, with online viscosity testing system, the equipment is widely applicable to the domestic and foreign large and small corrugated board manufacturers.

Function Introduction:

1.This equipment is suitable for both one step and two-step automatic glue making.

2.The production process of glue is fully automatic to avoid the influence of human factors.

3.Ensure the quality of glue, improve production efficiency, reduce the loss of base paper.

4.Accurate weighing module combined with PLC program control to ensure accurate formula and accurate delivery of materials.

5.Simple operation, ordinary staff after a simple training can be the number of operations.

6.Multi-formula storage, according to the season, weather and paper factors to choose the glue formula.

7.Online viscosity control system.

8.Waste water reuse, energy saving and environmental protection.

9.Automatic formula selection, more convenient operation.

10.Powder pump transport starch, occupy a smaller area.

11.Automatic glue supply, ensure supply glue all the time.