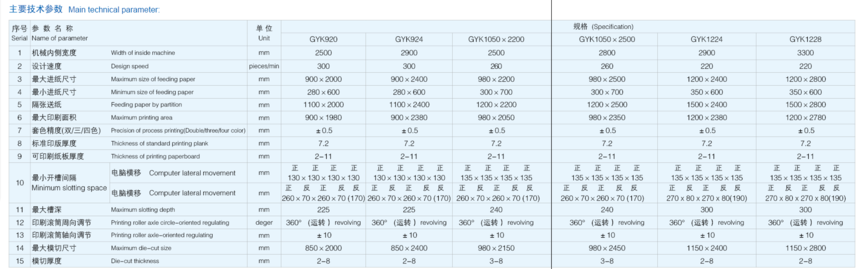

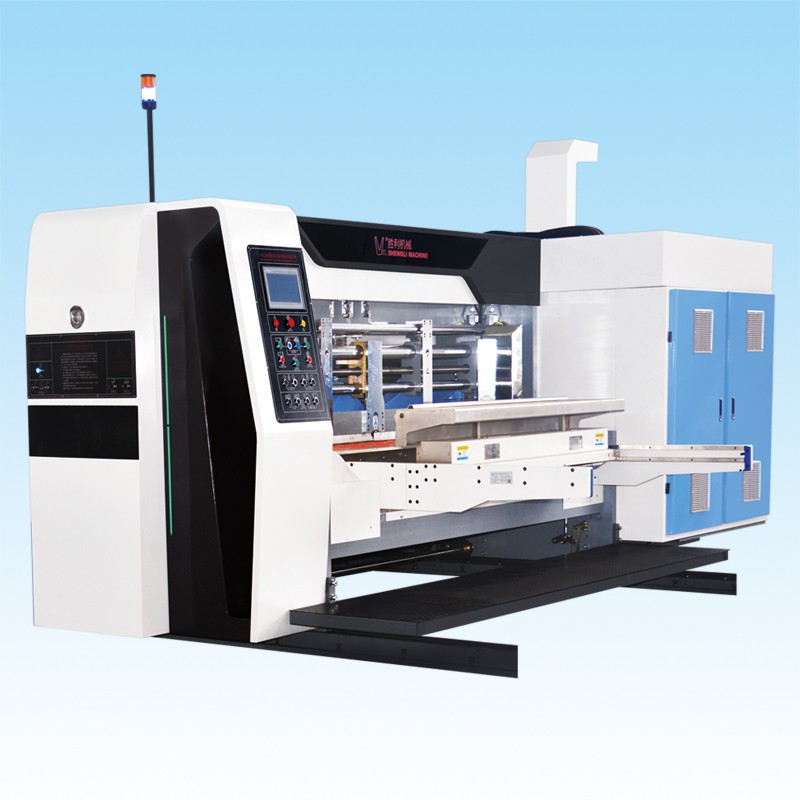

功能与特点:

功能与特点:

1、整机主要电器均采用法国施耐德产品。

2、采用前缘式送纸系统。

3、采用斜齿传动,齿轮经高频淬火,磨齿而成。

4、所有辊轴镀铬,增强硬度。

5、齿轮采用喷淋式循环润滑。

6、采用PLC、触摸屏多功能控制,采用变频控制器,精.确可靠。

7、自动归零,自动对版。

8、模块设计,多色印刷机组任意组合。

9、版辊横移采用电脑PLC控制。

10、刀模辊、软辊采用国际标准尺寸,通用性强,任何地方可购买到合适的模版及胶垫。

11、可选配单刮刀系统。

Function of Feeding Department:

1. Adopt three-axle lead-edge feeding .even accuracy, thin and bend paperboard easy to be feed in.

2. It can send the paperboard continuously or by partition equipped (with counting device).

3. Electric controlling the clutch of the machine platform and installed alams in order to assure the safe of the operating personnel while the bell rings constaintly during marching.

4. The electrical machinery of the main engine starts the protective device.(If the machine has not been locked.the main engine can not start revolving.)

5. The separating electrical machinery starts the protective device.(If the machine has been locked you can not start the separating electrical machinery.)

6. It can adjusting feeding paper running ,relieve feeding glue roller’s preesure.

7. dust collecting plant, brushes and the air blower can clear the dust and the paper scrap of the paperboard surface.

8. Left and right side blocking pland electric controll.

9. Back paperboard baffle up and down, front and back adopt electric adjustment.

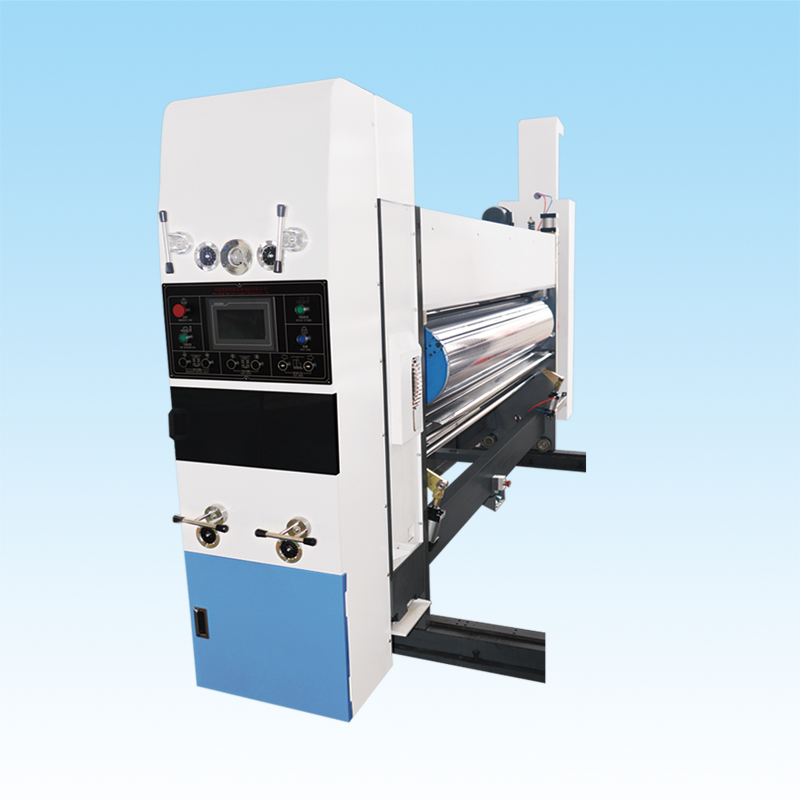

Function of Printing Department:

1. The printing roller and trace pressing roller adopt High quality steel material. To grind the surface and do the hard chrome plating.

2. To correct by dynamic balance, so the revolving is steady.

3. To load and unload the printing plating and step on the switch. Electric controlling the positive and negative revolving.

4. The space of the printing & pressing roller can be adjusted by hand. The scale panel shows the data.

5. Phase-adjusting mechanism, planet type gear structure.

6. To adopt PLC & touching screen to control the printing phase by the way of electric digital type 360 degrees adjustment. Automatic plate correcting,automatic zero returning and high speed phase adjusting.

7. Printing phase fixed device, pneumatic brakes.While the machine separates or the phase is adjusting, the brakes can restrict the revolving of the machine platform and keep the fixed point of the original gears' position.

8. The distance of the horizontal adjusting the printing roller is 20 mm.

9. Rubber roller: The surface of the roller is steel pipe which is packed by the wear-resisting rubber. Adopting medium and high special grinding the rubber roller has effective ink-spreading.

10. Steel material net-grain roller: Steel pipe surface grinding. Press and make net-grain, hard chrome plating.

11. It sets up inking rollers rotation electric machine. Keeping main machine from stopping water and ink turning dry.

12. Optional single blade system.

Function of Slotting Department:

1. Slotting phase adjusting mechanism,planet type gear structure.

2. Slotting phase is controlled by PLC & touching screen and adjusted by the way of electric digital type 360 degrees.(It can be adjusted while revolving and stopping.)

3. The space of the line-pressing wheel can be adjusted by hand.The scale panel shows the adjusted data.

4. The space of the slotting knife-stand can be adjusted by hand.The scale panel shows the adjusted data.

5. The width of the slotting knife is 7.0mm and made of alloy steel material.Under heat treatment blade grinding.hackles and double blades side repairing knife are very sharp and of long using life.

※ Electrically type:The width of the slotting and the line-pressing four axle adjusted by electrically synchronously.The height of paper chest four axle adjusted by electrically synchronously.

※Ordinary type:opening slot,pressing line,distance inserting board type.Four axles are adjusted by hand synchronously.Chest height four knives by hand adjusted synchronously.

Function of Rotary Die Cutting Department:

1. Die-cut phase and the gap between the cutter mould rollers are both controlled by computer, which can display but also can to set up.

2. The cushion roller adopts mechanical camdrum portable structure (40mm).

3. The gap between the cushion roller and the cutter mould roller adopts electrical adjustment.When stopping feeding paper, the soft roller will rise automatically; When working,the soft roller will return to the working position.

4. Adopt compentating system.No matter how much the cushion diameter changes,the speed of the cushion compentate and follow automatically, without adjustment by man.

5. With restoration for cushion after wear and tear.Keeping the surface of the cushion smooth.

6.Optional free version slotting function.

The function of vibrator stripping machine:

1.The vibrating chip remover adopts a design of multiple circular belts on top and bottom, and the cardboard passes through the middle.

2.Independent motor control vibration shaft, adjustable speed.

3.Equipped with 2 axial flow fans, it can effectively remove residual paper scraps on the surface of the cardboard.

4.The lower part of the vibrating machine has a conveyor belt for transporting waste paper, which concentrates and horizontally discharges the waste.

Hydraulic Stacker:

1. Bin arm using pneumatic operation, manual control.

2. Bedtable lifting, hydraulic station double hydraulic cylinder drive, to ensure the safety of operators.

3. Stacking, using a flat wrinkles climbing belt and steel clamping device, so that the stacking order and tidy.

4. Hold paper feeder can be adjusted to hold the opening width, with a batch accumulation function.

5. The use of side shoot baffles to ensure more orderly stacked cardboard.

6. Electric enforce the use of PLC programming control, independent of the operating electric box.

7. Optional vibration stripping and lateral waste function.

8.Stacker height: 1600mm.